How to Prepare for Your Custom Metal Project: A Step-by-Step Guide

Understanding Your Vision

Embarking on a custom metal project is an exciting journey that allows you to bring your unique vision to life. The first step in preparing for your project is to clearly define what you want to achieve. Consider the purpose of the project and how it will fit into its intended space. Whether it's a piece of art, a functional item, or structural work, understanding your vision is crucial.

Take the time to research and gather inspiration. Look at different styles, materials, and designs to see what resonates with you. Creating a mood board can be incredibly helpful in visualizing your ideas and communicating them to your metal fabricator.

Choosing the Right Materials

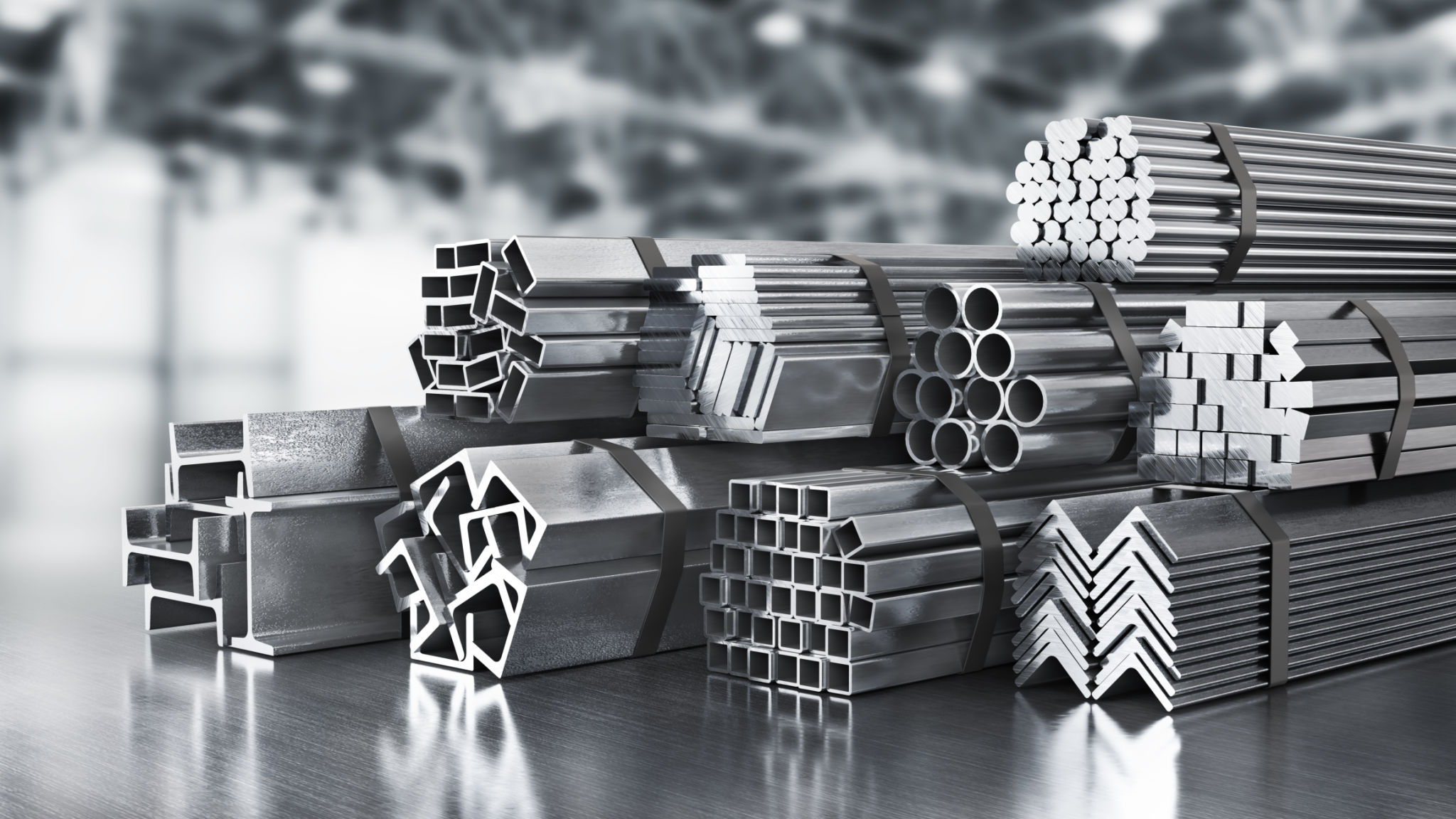

Once you have a clear vision, the next step is selecting the right materials for your project. The choice of material will significantly impact the project's aesthetics, durability, and cost. Common materials include steel, aluminum, brass, and copper, each with its own set of characteristics and applications.

Consider factors such as the project's location (indoor vs. outdoor), exposure to elements, and any specific functional requirements. Discuss these aspects with your metal fabricator to ensure you make an informed decision.

Establishing a Budget

Budgeting is a critical component in preparing for your custom metal project. Determine how much you're willing to invest and allocate funds for different aspects such as materials, labor, and any additional finishes or treatments. It's important to communicate your budget constraints early on to avoid unexpected expenses later.

Remember that while cost is an important factor, quality should not be compromised. Investing in high-quality materials and skilled craftsmanship can ensure the longevity and success of your project.

Finding the Right Fabricator

Choosing the right metal fabricator is essential for bringing your vision to life. Look for experienced professionals who have a solid portfolio of past projects similar to yours. Reading reviews and seeking recommendations can also help in making an informed decision.

Schedule consultations with potential fabricators to discuss your project in detail. This is an excellent opportunity to gauge their understanding, expertise, and ability to meet your expectations.

Designing and Planning

Once you've selected a fabricator, collaborate with them to develop detailed designs and plans. This stage involves finalizing dimensions, selecting finishes, and ensuring all technical aspects are addressed. A comprehensive plan will serve as a blueprint throughout the production process.

Consider engaging a designer or engineer if your project requires complex structural or aesthetic elements. Their expertise can help refine your ideas and ensure feasibility.

Setting a Timeline

Establishing a realistic timeline is crucial for keeping the project on track. Discuss timelines with your fabricator and factor in any potential delays due to material availability or unexpected challenges. Clear communication throughout the process can help manage expectations.

A well-defined timeline will not only keep the project organized but also allow you to plan other aspects around its completion date.

Final Preparations

Before production begins, review all plans and agreements with your fabricator. Ensure that every detail aligns with your vision and expectations. It might be beneficial to have a final walkthrough of the project site if applicable.

Make sure all necessary permits or approvals have been obtained if required by local regulations. This step is often overlooked but essential for avoiding legal complications.

Monitoring Progress

During production, maintain regular communication with your fabricator to monitor progress. Visits to the workshop can provide insights into the development process and allow for adjustments if needed.

Your involvement during this stage ensures that the project stays true to your vision and allows you to address any issues promptly.

Completion and Installation

Upon completion, conduct a thorough inspection of the finished product to ensure it meets your standards. Discuss installation procedures with your fabricator, especially if specialized equipment or expertise is required.

Once installed, take the time to admire your custom metal creation—a testament to careful planning, collaboration, and creativity.